The Principal Stones Used in the Mechanical Arts –

The Thanks of the Society were voted to R. Knight, Esq., for a Collection of Hone-Stones and Grind-Stones, presented by him; together with the following Descriptive Catalogue of them.

Sir, Foster Lane.

In compliance with your request, I have sent, for the Society’s acceptance, a collection of all the principal stones used in the mechanical arts, and of which the following is the catalogue. I have arranged them under two heads, viz. arenaceous and schistose: the few that do not come under either of these heads are separately described, and I shall be happy to give you any further information I am able on the subject.

I am, &c. &c.

Richard Knight.

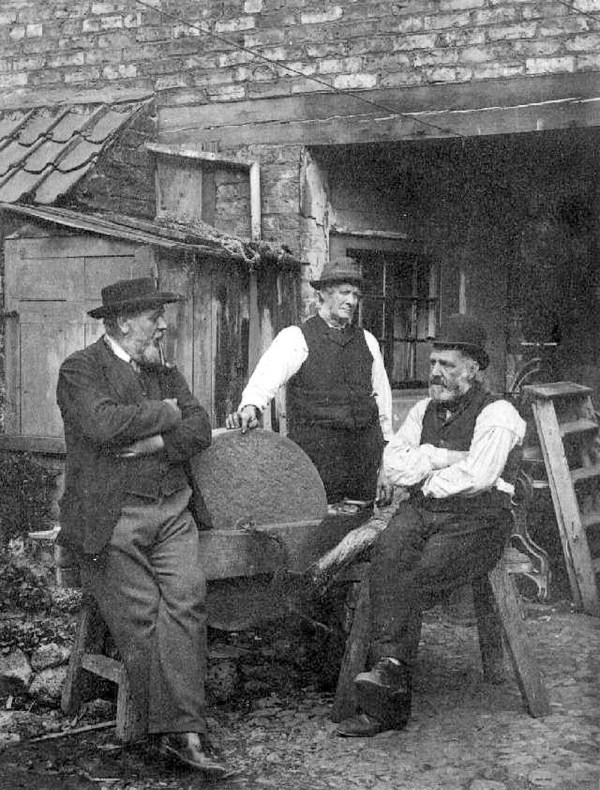

1. Grit or Sandstone.— Of this variety the universally known and justly celebrated Newcastle grind-stones are formed. It abounds in the coal-districts of Northumberland, Durham, Yorkshire, and Derbyshire; and is selected of different degrees of density and coarseness, best suited to the various manufactures of Sheffield and Birmingham, for grinding and giving a smooth and polished surface to their different wares.

2. Is a similar description of stone, of great excellence. It is of a lighter colour, much finer, and of a very sharp nature, and at the same time not too hard. It is confined to a very small spot, of limited extent and thickness, in the immediate vicinity of Bilston, in Staffordshire, where is lies above the coal, and is now quarried entirely for the purpose of grind-stones.

3. Is a hard close variety, known by the name of carpenters’ rub-stone; being used as a portable stone for sharpening tools by rubbing them on the flat stone instead of grinding. It is also much employed for the purpose of giving a smooth and uniform surface to copperplates for the engraver.

4. Is a much softer variety of sand-stone, usually cut into a square form, from eight to twelve inches long, in which state they are used dry by shoe-makers, corkcutters, and others, for giving a sort of coarse edge to their bladed knives, and instruments of a similar description.

5. A stone of similar properties, but of a more compact and harder description, and therefore better adapted for sharpening agricultural instruments, and may be used with or without water.

6. A porous fine-grained sand-stone, in considerable repute, from the quarries of Black Down Cliffs, near Collumpton, and well known by the name of Devonshire Batts.

7. Is a variety called Yorkshire Grit. It is not at all applied as a whet-stone, but is in considerable use as a polisher of marble, and of copper-plates for engravers.

8. Is a very similar stone, of a softer nature, and made use of by the same description of workmen, and is called Congleton Grit.

9. Norway rag-stone. This is the coarsest variety of the hone slates. It is imported in very considerable quantity from Norway in the form of square prisms, from nine to twelve inches long, and one to two inches diameter, gives a finer edge than the sand-stones, and is in very general use.

10. Charley Forest-stone is one of the best substitutes for the Turkey oil-stone, and much in request by joiners and others, for giving a fine edge. It has hitherto been found only on Charnwood Forest, near Mount Sorrel, in Leicestershire.

11. Ayr-stone, Scotch-stone, or snake-stone, is most in request as a polishing stone for marble and copperplates; but the harder varieties have of late been employed as whet-stones.

12. Idwall, or Welsh oil-stone, is generally harder, but in other respects differs but little as a whet-stone from the Charley Forest; but in consequence of its being more expensive, is in less general use. It is obtained from the vicinity of Llyn Idwall, in the Snowdon district of North Wales.

13. Devonshire oil-stone is an excellent variety for sharpening all kind of thin-edged broad instruments, as plane-irons, chisels, &c., and deserves to be better known. This stone was first brought into notice by Mr. John Taylor, who met with it in the neighbourhood of Tavistock, and sent a small parcel to London for distribution; but for want of a constant and regular supply, it is entirely out’of use here.

14. Cutler’s green hone is of so hard and close a nature, that it is only applicable to the purposes of cutlers and instrument-makers, for giving the last edge to the lancet, and other delicate surgical instruments. It has hitherto been only found in the Snowdon mountains of North Wales.

15. German razor-hone. This is universally known throughout Europe, and generally esteemed as the best whet-stone for all kinds of the finer description of cutlery. It is obtained from the slate mountains in the neighbourhood of Ratisbon, where it occurs in the form of a yellow vein running virtually into the blue slate, sometimes not more than an inch in thickness, and varying to twelve and sometimes eighteen inches, from whence it is quarried, and then sawed into thin slabs, which are usually cemented into a similar slab of the slate, to serve as a support, and in that state sold for use. That which is obtained from the lowest part of the vein is esteemed the best, and termed old rock.

16. The same, with the hone in natural contact with the slate.

17. Is a dark slate of very uniform character; in appearance not at all laminated; is in considerable use among jewellers, clock-makers, and other workers in silver and metal, for polishing off their work, and for whose greater convenience it is cut into lengths of about six inches, and from a quarter of an inch to an inch or more wide, and packed up in small bundles of from six to sixteen in each, and secured by means of withes of osier, and in that state imported for use, and called blue polishing stones.

18. Is a stone of very similar properties, but of a somewhat coarser texture and paler colours, and thence termed grey polishing-stone. Its uses are the same, and they are manufactured near Ratisbon.

19. Is a soft variety of hone-slate, the use of which is confined to curriers, and by them employed to give a fine smooth edge to their broad and straight-edged knives for dressing leather. They are always cut of a circular form, and are called Welsh clearing-stone.

20. Turkey oil-stone. This stone can hardly be considered a hone-slate, having nothing of a lamellar or schistose appearance. As a whet-stone, it surpasses every other known substance, and possesses, in an eminent degree, the property of abrading the hardest steel, and is at the same time of so compact and close a nature, as to resist the pressure necessary for sharpening a graver, or other small instruments of that description. Little more is known of its natural history than that it is found in the interior of Asia Minor, and brought down to Smyrna for sale.

21. The French Burr mill-stone, so justly esteemed as the best material for forming mill-stones for grinding bread-corn, having the property of separating a larger proportion of flour from the bran than can be effected by stones formed from any other material.

22. Conway mill-stone very much resembles the French in appearance. A quarry of this was opened near Conway, about twenty years since, which at first appeared very promising; but it was soon discovered that it was the upper stratum only that possessed the porous property so essential, the lower stratum being found too close and compact to answer the purpose.

23. Cologne mill-stone. This substance is an exceedingly tenacious porous lava. Mill-stones are made of this material in great quantity near Cologne, and transported by the Rhine to most parts of Europe. Smaller stones, from eighteen inches to thirty, are much used for hand mills in the West Indies for grinding Indian corn, for which purpose they are well adapted.

24. Emery-stone. No substance is better known, or has been subservient to the arts for a longer period, than this. The gigantic columns, statues, and obelisks of Egypt owe their carved and polished forms and surfaces to the agency of emery. It is obtained almost entirely from the island of Naxos, where it occurs in considerable abundance, in detached irregular masses. It is reduced to the state of powder by means of rolling or stampingmills, and afterwards by sieves and levigation.

25. Pumice-stone is a volcanic product, and is obtained principally from the Campo Bianco, one of the Lipari islands, which is entirely composed of this substance. It is extensively employed in various branches of the arts, and particularly in the state of powder, for polishing the various articles of cut glass; it is also extensively used in dressing leather, and in grinding and polishing the surface of metallic plates, &c.

26. Rotten-stone is a variety of Tripoli almost peculiar to England, and proves a most valuable material for giving polish and lustre to a great variety of articles, as silver, the metals, glass, and even, in the hands of the lapidary, to the hardest stones. It is found in considerable quantities both in Derbyshire and South Wales.

27. Yellow Tripoli, or French Tripoli, although of a less soft and smooth nature, is better adapted to particular purposes, as that of polishing the lighter description of hard woods, such as holly, box, &c.

28. Touch-stone is a compact black basalt or Lydianstone, of a smooth and uniform nature, and is used principally by goldsmiths and jewellers as a ready means of determining the value of gold and silver by the touch, as it is termed—that is, by first rubbing the article under examination upon the stone, its appearance forms some criterion; and, as a further test, a drop of acid, of known strength, is let fall upon it, and its effect upon the metal denotes its value.

29. Blood-stone is a very hard, compact variety of hematite iron ore, which, when reduced to a suitable form, fixed into a handle, and well polished, forms the best description of burnisher for producing a high lustre on gilt coat-buttons, which is performed in the turning-lathe by the Birmingham manufacturers. The gold on china ware is burnished by its means. Burnishers are likewise formed of agate and flint; the former substance is preferred by bookbinders, and the latter for gilding on wood, as picture-frames, &c.

Transactions of the Society Instituted at London for the Encouragement of Arts, Manufactures, and Commerce, Volume 50 – 1836

—Jeff Burks