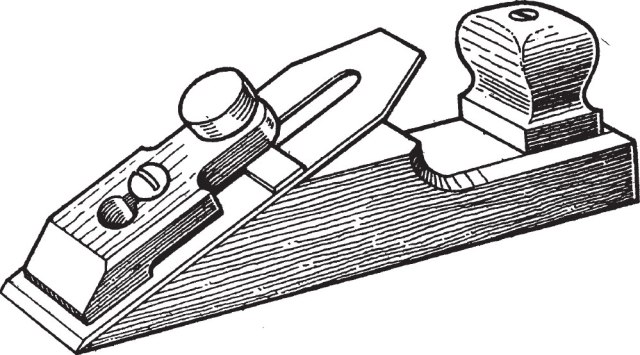

The Edge Plane –

This is an excerpt from “The Woodworker: The Charles H. Hayward Years: Volume I” published by Lost Art Press.

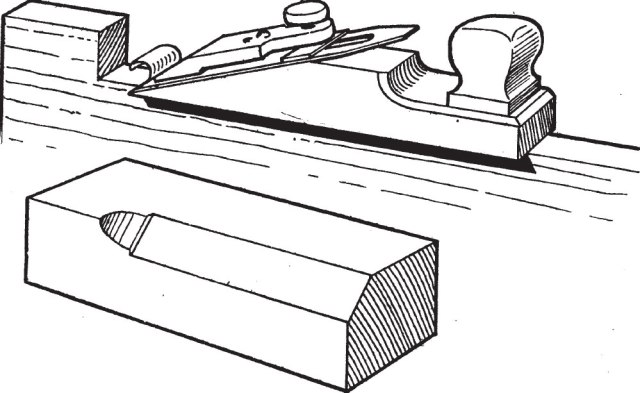

Two ways in which the plane would come in handy are shown in Fig. 2. In the one the plane is smoothing right up to an internal corner, and in the other is a stopped chamfer in which the plane could work right up to the stop. Many other uses will suggest themselves— such as trimming a stopped rebate.

It will be realized that it cannot be used in place of the more normal type of plane; it would dig in and fail to produce a flat surface. Furthermore, it could not be started. It is suitable only for working into a corner after the main surface has been planed. The great secret of its successful use is to press well down on the handle. Only in this way is it possible to avoid digging in. Then, the cutter must be set fine—sometimes without any projection at all—and gradually fed forwards. It usually happens in this sort of work that the corner is high, and that is why it will sometimes cut when there is no projection to the cutter at all.

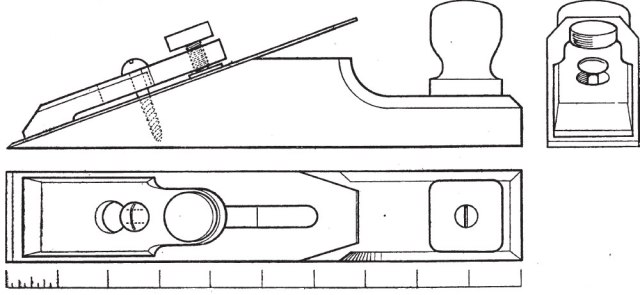

Fig. 3 shows the plane to scale. The main stock which should be of hardwood finishes 10 ins. by 1-3∕4 ins. square. Allow the width a trifle full for trimming and cut the front to an angle of 20 deg. Also shape the back. Finish neatly with a chamfer. The clamp is 4-1∕4 ins. by 1-1∕ 2 ins. by 1∕ 2 in. It has a hole and slot cut through it to enable it to be slipped over screw head and pushed forward into place. The thumbscrew can be any convenient screw, the hole for it having the thread forced in it. Bore a hole to the narrowest part of the thread and force the screw into it.

— MB